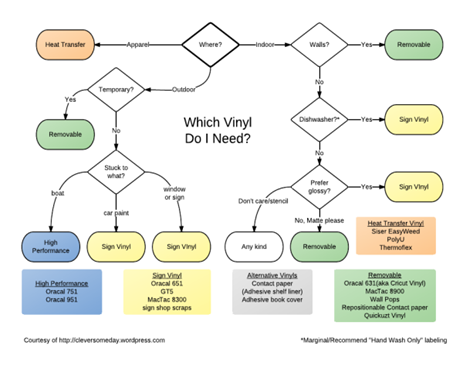

For awhile I was experimenting with vinyl cutting with some scraps that I was lucky to rescue from the recycling bin at my work. When I purchased my BossKut Cutter, it was originally intended just for paper and cardstock. Sticker cutting was not part of the plan. When I decided to get into producing and selling some decals, then it became research to finding the best vinyl to use for my customers. I found that this flowchart created by a great blog Clever Some Day easily sums up what is the best vinyl for your application. If you follow the link, she has a PDF that you can download and print for your reference.

Friday, November 27, 2015

Friday, November 20, 2015

Friday, November 13, 2015

Learning to Work in an Open Environment

I work at a 3rd Tier Electronics Company Manufacturer and the culture style is an open environment. The primary purpose of offices who adopt an open environment workspace is to make is easy for team members to have open communication and easy collaboration of ideas. This isn’t for everyone. There are more distractions, noisy and more transparency between colleagues. However despite the potential drawbacks, it’s an environment that works for my company and most of us thrive in this culture.

As a introvert, I had to adapt and developed a few things that helped me focus at the tasks on hand

Develop a ‘Invisible Wall’

People chat more in a open environment and often a lot longer then talking about the weather. To get out of these conversations, these often work:

- Wearing headphones

- Put up a sign

- Block it out on your calendar (to avoid people booking your time)

- If you use intercompany communicator – set yourself as ‘busy’

- Close your email software – if it’s an emergency, they’ll find you

Step Away from the Desk

None of us are chained at our desks. For more in-depth conversation with details that shouldn’t be shared, have it at a coffee shop or a spare meeting room. Sometimes I borrow a company laptop and I work in spare room from time to time.

Personalize Your Work Space

Since we are at work 30% of the time 5 days a week, it’s natural to want to enjoy our space. Bring a plant, small aquarium, pictures or decorations, things that that are acceptable for your company.

For me, I have a Lego mini-figure collection based on the Marvell super heroes. Yes, I do play with them

Work During Quieter Times

Adjust your hours when it’s more quiet, maybe earlier before most people arrive or later when most people left for the day. This ensures interruption time to focus on your projects. Or once in a while and if you have work that flexible enough, work from home.

Friday, November 6, 2015

Banned Laser Cutting and Engraving Material

* Jumping on Soapbox *

One of the first things we need to know before even using any laser is what material you can or shouldn’t engrave or cut. When you receive your Glowforge or any other laser cutting machine, the temptation of “playing with your new toy” is so tempting.

This is NOT A TOY.

Anyone wants to play without reading the manual and understanding the hazards are at risk for self injury, injury of others and danger of a fire

* Jumps off the Soapbox *

I apologize, this is in response after reading the community forums on both Etsy and Glowforge citing how excited they are about their machine or rejecting it because of how dangerous they feel it is. My fear is people not reading the manual and cut material that will seriously harm them, children or even burn down their homes. I don’t want to project my paranoia to you, but I rather make us novices stop and think. As devil’s advocate, if you follow precautions, a laser machine will be very safe as long as you keep an eye on it while it’s running

On to the subject of this post:

I thought I could do is cut my decal designs and replace my BossKut machine if I figured out not cut past the liner. The decals will be much more precise and could sell much more complicated designs. Unfortunately, it’s not going to happen. I read on the forums a big warning from more experienced users not to cut PVC. PVC will emit chlorine gas which will damage your lungs and corrode the machine.

So since vinyl cannot be put into a laser machine, I wanted to know what else couldn’t. Below is a list summarized after finding these repeated among many different laser services and manufacturers as extremely hazardous to humans and the machine

| Material | Health & Danger Issues | Material & Machine Issues | Examples |

| PVC (Poly Vinyl Chloride) Vinyl Pleather Artificial leather | Emits pure chlorine gas | Ruins optics Corrodes metal damages motion control system | It’s the most widely used plastic. Good list of examples on Mommy’s Footprint Blog |

| Polycarbonate / Lexan | Catches fire | Absorbs infrared radiation Cuts Poorly Discolors | Water Bottles Greenhouses CD, DVD, Blue Ray Safety Googles |

| ABS (Acrylonitrile Butadiene Styrene) | Emits cyanide gas Melts | Cuts poorly Melts doesn't vaporize Melted material deposit will burn inside the machine | Lego Some 3D Printing Filaments Toy instruments Pipes |

| HDPE (High-density polyethylene) | Catches fire melts | Melts doesn't vaporize Melted material deposit will burn inside the machine | Milk bottles Water Jugs Household cleaner bottles margarine tubs |

| Polystyrene Foam | Catches fire melts | Melts doesn't vaporize Melted material deposit will burn inside the machine | Foam packaging, Styofoam takeout containers and cups craft pompoms reusable bags |

| Polypropylene Foam | Catches fire melts | Melts doesn't vaporize Melted material deposit will burn inside the machine | construction insulation |

| Fiberglass | Emits fumes | Glass cannot be cut Epoxy emits the fumes | pools boats car parts insulation |

| Carbon Fiber | Emits noxious fumes | Carbon fiber cuts poorly | car parts pools bathtubs |